Cleaning Outboard Motor Cooling System: Comprehensive Guide for Optimal Maintenance

The cooling system of an outboard motor is a critical component that ensures engine longevity and performance. Saltwater, mineral deposits, and marine debris can clog cooling passages, leading to overheating, corrosion, and costly repairs. This guide provides a detailed, step-by-step approach to cleaning outboard motor cooling system, incorporating mechanical, chemical, and preventive methods. Backed by expert insights from marine manuals and technical resources, you’ll learn how to maintain optimal water flow, select effective cleaning products, and implement best practices for year-round reliability.

Why Cleaning Outboard Motor Cooling System is Essential

Risks of a Clogged Cooling System

A neglected cooling system compromises heat dissipation, causing engine overheating that damages seals, cylinders, and the thermostat. Salt crystallization abrasively wears down the water pump impeller, while limescale buildup insulates metal surfaces, reducing heat transfer efficiency by up to 40%. In severe cases, blockages can lead to catastrophic engine failure, particularly in saltwater environments.

Signs Your Cooling System Needs Attention

Key indicators that it’s time to clean an outboard motor cooling system include:

- Weak or irregular exhaust water flow, signaling restricted circulation.

- Unusual whistling noises during acceleration, caused by pressure buildup from obstructions.

- White residue around coolant fittings or the heat exchanger, indicating mineral deposits.

Methods Cleaning Outboard Motor Cooling System

Preparation: Safety and Tools

Always disconnect the battery and allow the engine to cool for at least one hour before servicing. Essential tools include:

- Flush muffs or a flush port adapter to connect a garden hose.

- Chemical cleaners like Salt-Away or a vinegar-Dawn solution for descaling.

- Soft-bristle brushes, a plastic scraper, and replacement gaskets for mechanical cleaning.

Mechanical Cleaning: Disassembly and Manual Removal

For severe blockages, partial disassembly may be necessary:

- Drain the cooling system by removing the intake grilles and thermostat housing.

- Extract the heat exchanger tube bundle and scrub internal passages with a nylon brush to remove debris.

- Inspect the water pump impeller for wear and replace if blades are cracked or stiff.

This method restores up to 90% of original water flow but requires careful handling of gaskets and seals to prevent leaks.

Chemical Flushing: Products and Procedures

Non-invasive solutions dissolve deposits without disassembly:

- Vinegar and Dawn mixture: Combine 1 part white vinegar with 2 parts water and a tablespoon of Dawn dish soap. Circulate through the system for 20–30 minutes to break down salt and grease.

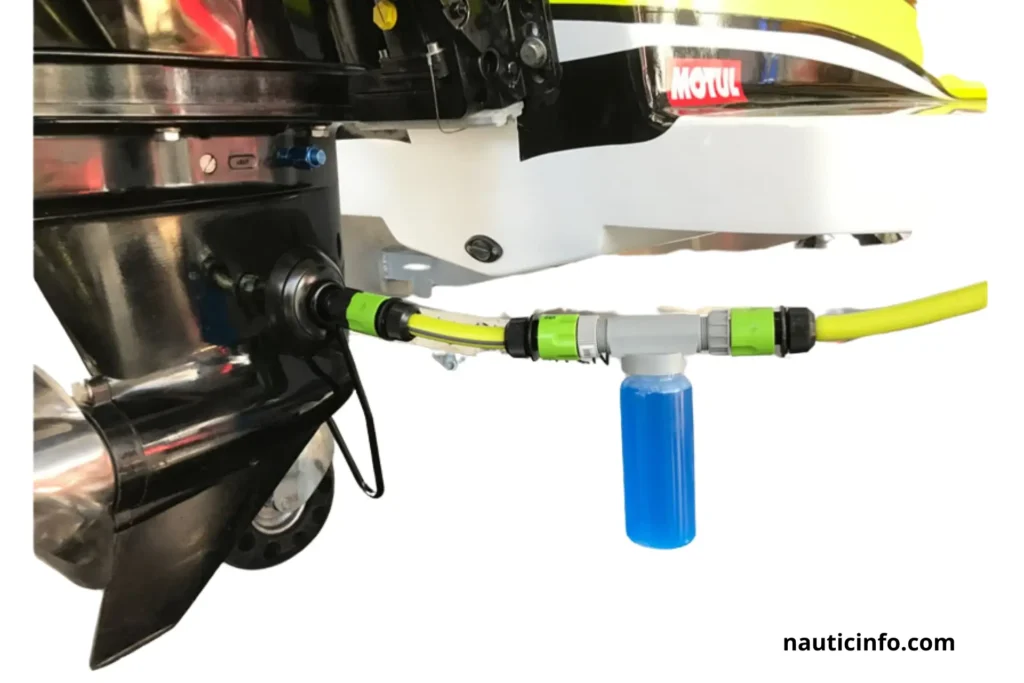

- Salt-Away Engine Flush: This biodegradable solution neutralizes salt and prevents corrosion. Attach the dispenser to a flush port and run the engine for 15 minutes.

After chemical treatment, rinse thoroughly with freshwater to eliminate residue.

Preventive Flushing: Techniques and Frequency

Regular flushing is the most effective way to avoid buildup:

- Post-use freshwater rinse: Connect flush muffs to a garden hose and run the engine for 10 minutes to expel salt and debris.

- Monthly deep flush: Use a salt-neutralizing agent like Salt-Away during rinsing to protect internal components.

- Annual heat exchanger soak: Submerge the tube bundle in a descaling acid bath overnight for thorough mineral removal.

Cleaning Outboard Motor Cooling System.

Optimizing Maintenance: Schedules and Best Practices

Recommended Cleaning Frequency

- After every saltwater use: Flush with freshwater.

- Every 6 months: Perform a chemical flush.

- Every 2–3 years: Disassemble and manually clean the cooling system.

Common Mistakes to Avoid

- Using high-pressure water: This can damage the heat exchanger’s delicate fins.

- Mixing coolant types: Incompatible formulas may gel, worsening blockages.

- Skipping impeller inspections: A worn impeller reduces water flow, accelerating overheating.

Cleaning Outboard Motor Cooling System.

Conclusion: Proactive Care for Peak Performance

Cleaning an outboard motor cooling system is a non-negotiable practice for safeguarding your engine’s health. By combining routine flushing, targeted chemical treatments, and periodic mechanical inspections, boaters can prevent overheating, extend engine life, and avoid expensive repairs. For saltwater enthusiasts, investing in a dedicated flush kit and eco-friendly cleaners like Salt-Away ensures reliable performance season after season. Always consult your engine’s manual for model-specific guidelines and schedule annual professional checkups to address hidden issues.