Inboard vs. Outboard Maintenance: The Fundamental Differences

Buying your first boat is often the realization of a lifelong dream. However, once the euphoria of signing the papers fades, a technical reality quickly imposes itself on the new owner: maintenance. This is often where the difference lies between a successful boating season and a series of painful repair bills. The choice of engine isn’t just a question of performance or aesthetics; it is, above all, a choice of mechanical lifestyle, inboard vs. outboard maintenance.

Indeed, although the end goal is the same—propelling your vessel—the mechanical philosophy opposing these two worlds is radically different. On one side, the compact, external outboard motor; on the other, the inboard engine, hidden deep within the bilge.

In this comprehensive article, we will break down, point by point, the realities of inboard vs. outboard maintenance. Our goal is clear: to give you the keys to understanding the specific constraints of each system so you can anticipate costs and required services.

Understanding Architecture to Better Manage Inboard vs. Outboard Maintenance

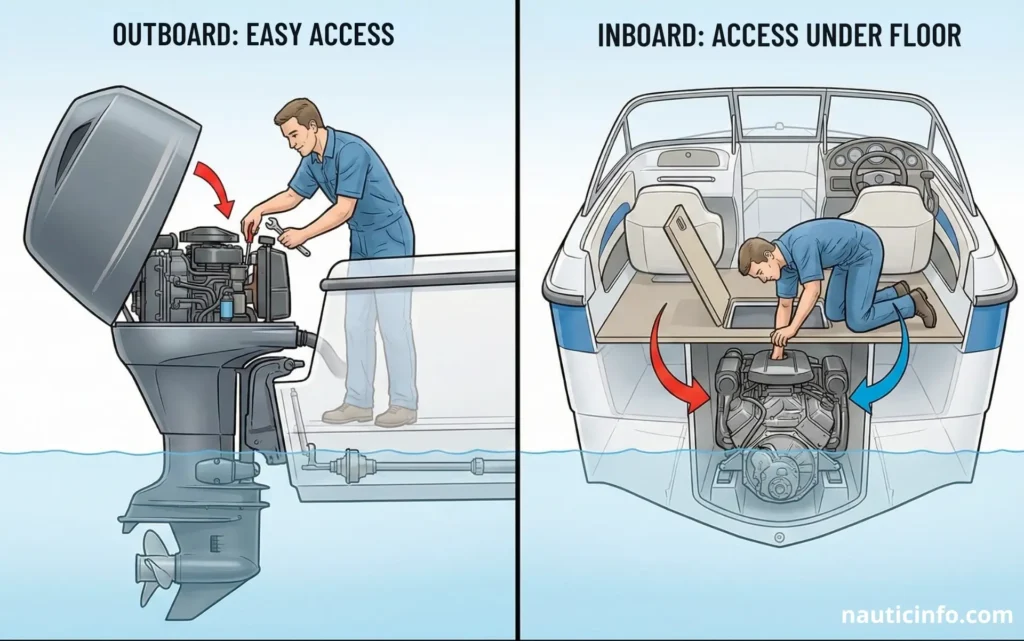

Before discussing oil changes or filters, it is essential to grasp the physical architecture of your propulsion system. In fact, the location of the engine dictates about 80% of the difficulties you will encounter during maintenance.

The Outboard Concept

The outboard motor is an “all-in-one” unit. The engine block, transmission, and propeller are grouped into a single housing located outside the boat, bolted to the transom. Consequently, access is immediate. You simply remove the top cowling to get a complete overview of the mechanics.

The Inboard Concept

Conversely, the inboard engine is installed inside the hull, often in the center or at the rear. It closely resembles a marinized automotive engine. The transmission passes through the hull via a propeller shaft (direct drive/V-drive) or an outdrive unit (sterndrive/I/O). Therefore, access is often constrained by the available space within the engine compartment.

Accessibility: The Key Factor in Inboard vs. Outboard Maintenance

When comparing inboard vs. outboard maintenance, accessibility is undoubtedly the most differentiating criteria for both amateur DIYers and professional mechanics.

The Ergonomic Advantage of the Outboard

Firstly, working on an outboard is generally much more comfortable. Since the engine is external, you can often perform maintenance while standing, with the boat on its trailer or in its slip. Furthermore, if a major breakdown occurs, the entire motor can be unbolted and transported to a shop without touching the boat’s structure. Thus, labor costs can sometimes be reduced because intervention time is optimized.

The Physical Challenge of the Inboard

In contrast, inboard maintenance often requires contortionist skills. Depending on the boat’s design, changing a simple water pump impeller or an oil filter might require dismantling floor panels, removing bench seats, or squeezing into tight, hot spaces. Consequently, mechanics often bill more hours for tasks that would seem simple on an outboard, simply due to the time required to gain access.

Cooling Systems: Nuances of Inboard vs. Outboard Maintenance

Cooling is the Achilles’ heel of any marine engine, especially in saltwater environments. This is where technical differences significantly widen regarding inboard vs. outboard maintenance.

Raw Water Cooling vs. Closed Cooling (Heat Exchanger)

The majority of modern outboards use direct raw water cooling (although high-horsepower models are evolving). This means saltwater circulates directly around the engine cylinders. Therefore, maintenance requires meticulous cleaning of the cooling system flushing with fresh water after every outing to prevent internal corrosion.

On the other hand, most inboard engines (especially diesels and newer gas engines) use a dual-circuit system with a heat exchanger (closed cooling). The engine block itself is cooled by coolant (antifreeze, like a car), and this coolant is, in turn, cooled by raw water via a heat exchanger.

- Inboard Advantage: The engine block is better protected from corrosion.

- Disadvantage: You have two circuits to maintain. The heat exchanger must be disassembled and cleaned periodically (every 3 to 5 years) to prevent scaling—a costly operation specific to inboard maintenance.

Winterization: A Critical Step in Inboard vs. Outboard Maintenance

When winterizing, the procedure differs significantly. For an outboard, gravity works in your favor: when tilted down vertically, the water drains naturally. For an inboard, it is imperative to manually drain the block, manifolds, and exchangers, and often fill them with non-toxic antifreeze. Overlooking this on an inboard can lead to a cracked engine block at the first freeze, an irreversible financial catastrophe.

Transmission and Sealing in Inboard vs. Outboard Maintenance

If the engine is the heart, the transmission is the muscle. And this is where the inboard, particularly in the sterndrive (I/O) version, presents heavy constraints regarding inboard vs. outboard maintenance.

The Relative Simplicity of the Outboard Lower Unit

On an outboard, transmission is direct to the lower unit gearcase. Maintenance is often limited to changing the gear lube and greasing the propeller shaft. There are no holes in the hull below the waterline for the drivetrain (other than mounting bolts), meaning fewer risks of major water intrusion.

The Critical Point of the Inboard: Bellows and Packing Glands

Inboard vs. outboard maintenance diverges totally regarding watertightness.

- Sterndrive (Inboard/Outboard or I/O): This system uses rubber bellows to ensure watertightness between the mobile outdrive and the transom. These bellows must be changed every 2 to 5 years. If the universal joint bellows tears, the boat can sink. It is heavy, costly maintenance requiring the boat to be hauled out of the water.

- Direct Drive (Shaft Inboard): Here, sealing is ensured by a stuffing box (packing gland) or a dripless shaft seal. Although generally more robust than a sterndrive, it requires periodic adjustment or replacement to prevent water from flooding the bilge.

Comparative Table: Transmission and Sealing

Component Outboard Inboard (Sterndrive/I/O) Inboard (Direct Drive) Transmission Fluid Change Simple (lower unit drain/vent screws) Simple, but often requires accessing internal reservoir N/A (Separate transmission) Critical Points Prop shaft seal Gimbal bearing & Bellows (Vital) Stuffing box / Dripless seal / Cutless bearing Risk of Water Intrusion Low High (if bellows are neglected) Medium (if stuffing box is neglected) Maintenance Cost Low High (significant labor involved) Medium

Costs and Budget: Financial Analysis of Inboard vs. Outboard Maintenance

This is often the decisive question for new owners: which one costs more? The answer isn’t binary, but it often leans in one direction when analyzing inboard vs. outboard maintenance.

The Cost of Parts vs. The Cost of Labor

Generally, replacement parts for modern outboard motors (especially complex 4-strokes) can be expensive. The technologies are advanced and compact.

However, analyzing inboard vs. outboard maintenance reveals that the inboard often costs more in labor. As mentioned previously, difficult access and the complexity of peripheral systems (heat exchangers, exhaust elbows, sterndrive bellows) lengthen service times. Additionally, gas inboard engines (often American V6 or V8 bases) can be thirsty for fuel, adding to the operating budget, even if their basic mechanical parts are sometimes cheaper because they are automotive-sourced.

Exhaust Manifolds and Risers: The Inboard “Tax”

There is a specific expense for inboards that outboard owners generally ignore: exhaust manifolds and risers (elbows). In contact with saltwater and hot exhaust gases, these cast-iron parts inevitably corrode. They must be replaced every 5 to 7 years in saltwater environments. The cost can range from $1,000 to over $3,000 depending on the model (V6 vs V8, OEM vs aftermarket). If this maintenance is neglected, water can revert into the cylinders and destroy the engine.

Practical Tips: Seasonal Routine for Inboard vs. Outboard Maintenance

To help you visualize the workload, here is a comparison of recurring tasks for inboard vs. outboard maintenance.

Checklist: Outboard Maintenance Routine

- After Every Outing: Flush with fresh water (using “earmuffs” or built-in flushing port).

- Monthly: Visual check of the prop (for fishing line), grease steering linkage.

- Annual (or every 100 hours): Engine oil and filter change, lower unit gear lube change, fuel filter replacement, check thermostat and anodes, grease pivot points.

Checklist: Inboard Maintenance Routine

- After Every Outing: Flush raw water circuit (if a flush kit is installed), visual check of the bilge (for oil or water leaks).

- Monthly: Check belt tension, coolant level, inspect raw water intake strainer.

- Annual (or every 100 hours): Engine oil change, fuel/water separator replacement, check raw water pump impeller, inspect anodes (engine and drive), check hose clamps for tightness due to vibration.

- Multi-Year: Replace manifolds and risers, clean heat exchangers, replace sterndrive bellows (I/O models).

Pros and Cons for the New Owner Regarding Inboard vs. Outboard Maintenance

To synthesize our analysis on inboard vs. outboard maintenance, let’s recap the strengths and weaknesses for a beginner.

The Outboard Choice

This is the choice of peace of mind and simplicity.

- For whom? Those who want to boat without spending their weekends head-first in the bilge. Ideal for most trailerable boats under 30 feet.

- The Trap: Do not neglect flushing. Salt is the #1 enemy of raw water cooling systems.

The Inboard Choice

This is the choice of onboard comfort (clear swim platform) and often diesel power for larger vessels or specific wake sports requirements.

- For whom? Experienced DIYers or those with a more elastic maintenance budget. Ideal for watersports (clean wake) and cruising.

- The Trap: Buying a used inboard boat without a documented maintenance history of the exhaust manifolds/risers and bellows.

Conclusion regarding Inboard vs. Outboard Maintenance

Ultimately, the inboard vs. outboard maintenance match does not designate an absolute winner, but it highlights two distinct philosophies. The outboard shines with its accessibility and ease of replacement, often making it the best ally for the new boater concerned with controlling their budget and time. The inboard, although more demanding and potentially costlier in labor, offers aesthetic advantages and boat balance that remain unrivaled for certain activities.

Therefore, before signing for your future vessel, don’t just look at the cabin cushions or the sleek lines of the hull. Lift the cowling or open the engine hatch. Ask yourself: “Am I ready to maintain this machine?” Your answer will determine the serenity of your future boating seasons.